The Definitive Guide to 24hr Media

Table of Contents24hr Media Can Be Fun For Everyone24hr Media Things To Know Before You Get ThisThe 7-Minute Rule for 24hr MediaWhat Does 24hr Media Mean?4 Simple Techniques For 24hr Media

Advancements in print innovation are transforming the interactions playing area when it concerns top quality, cost and advanced abilities. Balanced out printing and digital printing are the significant processes whereby print jobs are carried out both utilizing four-color printing approaches. Each choice has its advantages, offering various techniques to fulfill the requirements of diverse manufacturing jobs.

Commonly, this has actually been one of the most regular strategy for specifically maintaining shade suits, making it excellent for print runs that just call for fixed printing such as pre-printed types, sales brochures, leaflets, service cards, and bulk postcard mailings. Due to the fixed nature of litho printing, it is not suitable for variable print pieces that will be sent by mail to private receivers such as statements, letters, and personalized postcards.

A Biased View of 24hr Media

The most current innovations in print technology are helping to bring many of balanced out's advantages into the electronic printing globe absolutely changing the face of modern printing! There are some key differences between Offset Printing and Digital Printing.

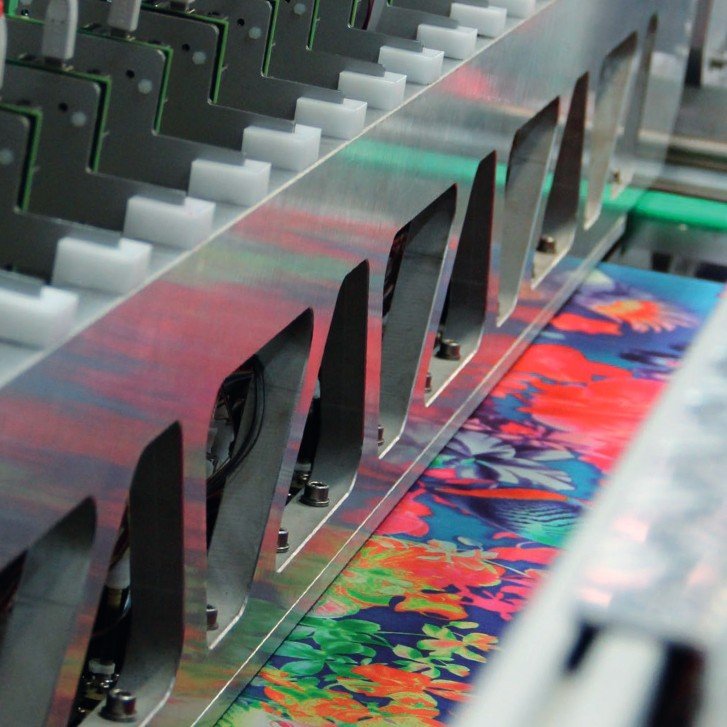

Today's electronic print tools is amongst one of the most sophisticated on the marketplace. Below are a few of the greatest benefits of using digital printing: dominate the digital print space, with full-color printing completed in one procedure and seamlessly published straight from a print documents. Without an extensive set up procedure, the calibration time of a certain task is shortened, contributing to quicker print time and total distribution.

The inkjet printing procedure has helped to transform the industry as well as the top quality and rate of the result. The most recent inkjet technology can print on conventional balanced out stocks with dull, silk, and shiny coatings. Top quality digital print paired with software-managed shade administration methods includes maximum worth to print pieces and makes manufacturing processes much more dependable than offset.

All about 24hr Media

(https://www.awwwards.com/za24media/)

Specific quantities of ink and printer toner are utilized to prevent waste. Eco-friendly and biodegradable inks and toners are also available for even more lasting printing. Digital print additionally gets rid of the demand to clean plates or blankets with dangerous chemicals at the end of the printing procedure. As the high quality of digital print services increases, the advantages become increasingly apparent and beneficial.

Variable information assists companies reach their specific consumers and audience with uniquely-created and individualized material. As technology improves, the high quality of digital printing has actually ended up being second-to-none, with greater information, color suit capabilities and total precision. Without the demand to clean plates or use excess ink, electronic printing is also much less wasteful and usually much more environmentally pleasant.

Conventional printing methods, such as countered lithography ("balanced out") and flexography ("flexo"), involve numerous make-ready steps to move an original photo to a substrate. These methods need the production of a collection of plates installed on a cyndrical tube to move ink that forms the preferred image when incorporated on paperboard and other packaging products. Window Vinyl.

24hr Media Can Be Fun For Anyone

Digital printing, with fewer moving items, is extra dexterous than countered in this respect.

Lowered set-up time saves money on the front end. And given that these are not large bulk orders, smaller sized services can afford to publish without having to meet the greater and much more expensive print limits of conventional printing.

Make certain you work together with a printing and packaging companion who has the ideal accreditations. While eleventh-hour printing and customization are a massive advantage, digital might not always be the most effective approach for you. Balance out printing has the advantage of cost-effectiveness with big print runs, particularly those with sophisticated attractive results and specialty finishings.

Some Ideas on 24hr Media You Should Know

Lithographic presses make use of 2 print platesa positive and a negativeto transfer top quality shade graphics onto an appropriate substrate. The favorable plate, with its smooth surface, brings in oil-based inks and pushes back water. On the other hand, the adverse plate, with its rough appearance, takes in water and repels oil. Rubber rollers are after that used to move the image from the plate to the corrugated surface area.

Corrugated paper can sometimes verify to be a challenging surface to publish on, but Litho prints to a separate surface area and is after that laminated to it, making it very easy to publish top notch images. It can be incredibly regular, even for long terms. The a lot more you publish, the less expensive the expenses come to be for Litho.

If you have enough time and budget plan, and a big quantity of a solitary design, then there shouldn't be a problem. What Litho does not offer you is exactly what Digital does, personalization. A lot more on that particular later on. Expensive established Longer turnaround No Variable Data Printing Smaller shade range, shades can be much less Continue intense Digital printing is the process of printing digital images directly onto the corrugated substrate using a single-pass, direct-to-corrugate method - Custom Boxes.